Global Ideas, Local Impact: Three Yanmar Solutions to Watch in 2026

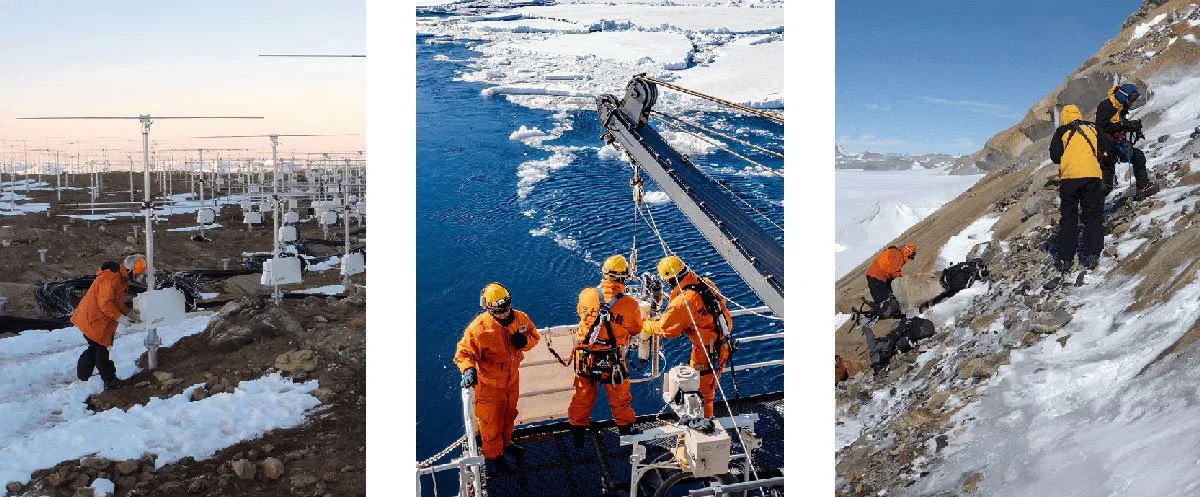

Yanmar in Antarctica

Built for Places Where Stopping Isn’t An Option.

If you ever need proof that Yanmar engines can handle tough conditions, look a long way south to Antarctica, because it doesn’t get much harsher than that.

What most people don’t know is that Yanmar has been supporting Japan’s Antarctic Research Program for more than 40 years, with engineers living at Syowa Station to keep the generators running through freezing temperatures, howling winds, and months of darkness. It’s a place where machinery doesn’t just work hard, it actually fights to stay alive.

And down there, power is everything. Heating, lighting, research equipment, water systems, communications…if the generators stop, the whole station stops. That’s why Yanmar engines were chosen in the first place, and why they’re still trusted today.

It all started with the 6RL-T diesel back in 1983, and since then Yanmar engineers have been on the ice every season looking after fuel systems, piping, preventative maintenance, and anything the environment throws at them.

For those of us back home in (cosy) NZ, whether you’re in construction, civil, agriculture, or industrial operations, it’s a good reminder of what Yanmar brings to the table: gear that keeps going, even when conditions say it shouldn’t. (If it works in Antarctica, it will work anywhere).

Need a generator that can withstand the harshest conditions?

Save the Farms

A challenge in Japan is one we understand in NZ.

Across Japan, a lot of productive farmland is at risk of being left unused as farmers get older and fewer young people step in to take over. And while the situation is different here in New Zealand, the theme is familiar - ageing workforces, rising costs, tougher environmental rules, and the ongoing question of who’s going to run the farm next?

Yanmar’s new SAVE THE FARMS project is their answer to the problem, and it’s an interesting one.

The idea is simple: find smarter, more sustainable ways to keep land productive and make farming a career people actually want to take on.

One of the standout solutions is agrivoltaics, installing solar panels high enough above the paddocks that crops and machinery can still operate underneath. Farmers keep using their land as usual, while also earning extra income from solar power. Combined with regenerative farming practices, it helps improve soil health, reduce emissions, and stabilise farm income.

Two types of trial sites are already running in Japan:

Yanmar-led farms, where abandoned land is brought back into production.

Farmer-led sites, where growers continue farming and Yanmar manages the solar side of things.

The early signs are promising, and local interest is high, especially from farmers who don’t want to give up their land but can’t keep running it the way they used to. And it’s great to see companies like Yanmar exploring practical ways to make agriculture more sustainable, more profitable, and more appealing for the next generation.

Yanmar Sensui-Kun Mark III

A Smarter, Easier Way to Clean Fish Farm Nets

Introducing Sensui-Kun Mark III by Yanmar

Anyone who works in aquaculture knows how fast nets can foul up, mussels, algae, barnacles etc. you name it. And once that build-up starts, everything gets harder: water flow drops, oxygen levels fall, fish slow down, and disease risks climb. It’s a constant battle on salmon farms and finfish sites right across New Zealand.

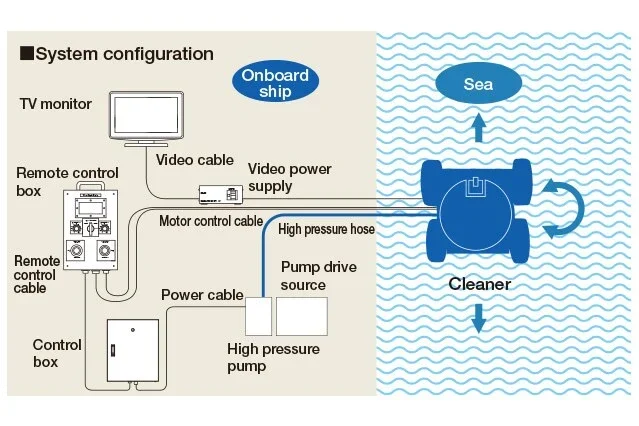

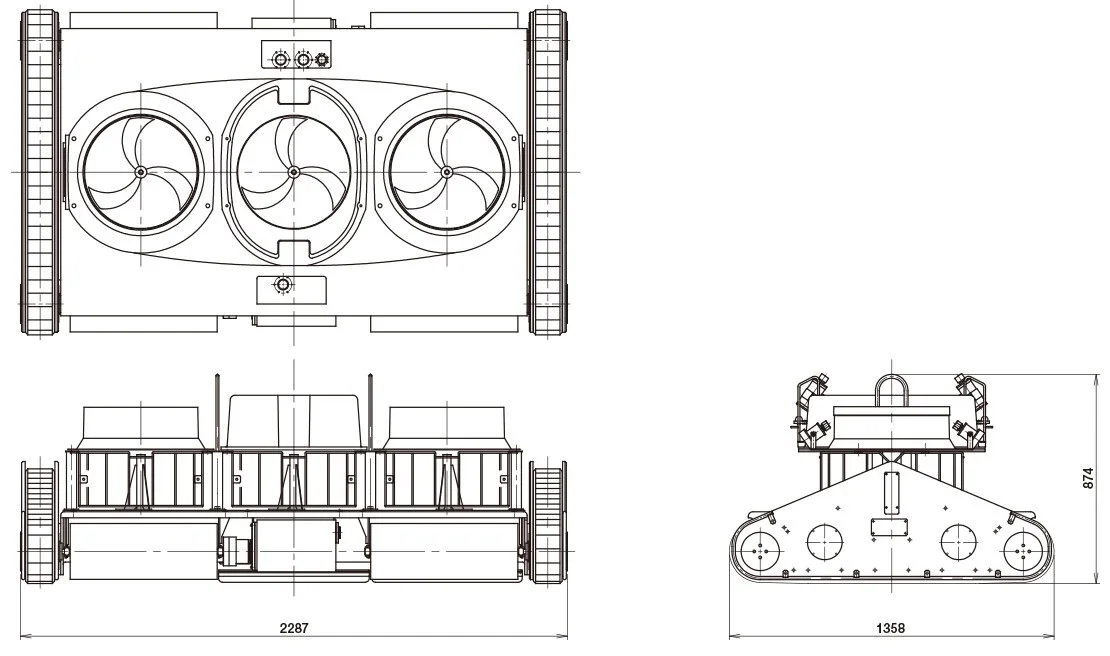

That’s where Yanmar’s Sensui-Kun Mark III comes in, a compact kit designed to save time, reduce risk, and make net cleaning a lot simpler.

Instead of hauling nets out or sending divers down, the Sensui-Kun is a self-propelled underwater robot that does the job with just one operator. It uses powerful water jets to clean both the sides and bottom of the cage nets, without disturbing the fish or adding chemicals to the mix.

Why cleaner nets matter

Keeping nets clear doesn’t just improve water quality, it directly impacts farm performance:

Better oxygen flow and healthier fish

Reduced parasite pressure

Less reliance on anti-fouling treatments

No risk of nets sinking under excessive biofouling weight

More consistent feeding behaviour and growth rates

These are challenges Kiwi aquaculture operators know well, and they’re exactly what the Sensui-Kun was built to address.

Simple to operate, easy to deploy.

The robot can be lowered into the pen through a small opening in predator nets, then controlled via an easy-to-use joystick. A live video feed gives operators full visibility of the cleaning process from the deck.

For farms looking to improve efficiency, reduce diver risk, and meet environmental standards, Yanmar’s net-cleaning technology offers a practical, reliable tool, one that’s already proving its value across international aquaculture operations.

Want to see if this would fit your aquaculture operation?